Carbon Fiber for Bikes

Bicycles have been around for centuries and have taken many shapes and forms through the years. The challenge has always been to build a better bike, and with the use of carbon fiber, that challenge is being met more than ever before!

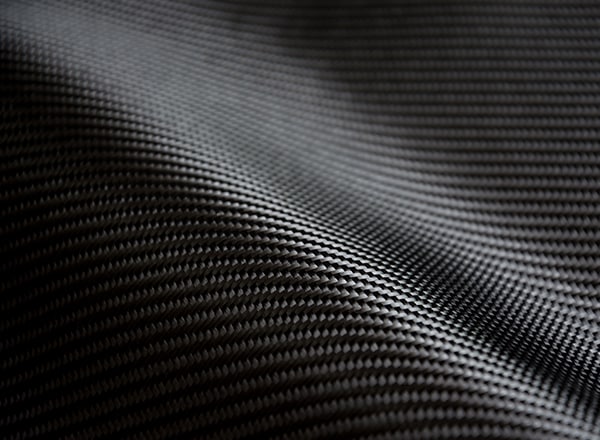

The use of carbon fiber in the manufacturing of goods and parts is a fast-growing industry. Though many are not aware of it, carbon fiber products are already in the world around us. From aerospace to race cars, many industries have found the lightweight, high-strength ratio of carbon fiber to be ideal for their manufacturing needs. This includes the world of the bicycle.

With improved bicycle manufacturing and repair techniques, carbon fiber bikes are no longer the bikes of the elite and wealthy. These lighter, faster bikes are now more affordable to the average biking enthusiast. Manufacturing bicycles with Carbon fiber allows for a stronger yet lighter frame, while also delivering comfort for the rider. This level of comfort sets a carbon fiber frame apart from its counterparts. The damping qualities of carbon fiber simply allow for a smoother ride. Manufacturing advancements in the epoxy and weave of carbon fiber allow designers to focus on areas of strength where bicycles need it most. With the addition of UV stabilizers, carbon fiber bikes no longer fade in the sun and can maintain their appearance throughout the life of the product. Carbon fiber material doesn’t rust or corrode like a metal bike would over time. And the most convincing argument for bikes made of carbon fiber in the modern world is that they are tried and tested and have passed with flying colors! The first all-carbon-fiber frame bike was built in 1986. When maintained properly, your carbon fiber manufactured bicycles can last a lifetime, which is why carbon fiber is becoming the most trusted component in the aerospace industry. You might not own a spaceship, but your bike is the next best thing!